MASTER ignition MAP sensor

Broad range ECU to control ignition and injection. For use in all types of motorcycles, go-karts, cars, motor-cross-seaters, simply for general use from hobby to professional racing and aircraft engines, turbines, cogeneration units, generating stations and other applications with 1-16 cylinders (depending on type). Easy installation and setup. Version P sensor with integrated pressure sensor -80 to 150kPa, led out of the box by nipple.

Technical Specification

In the documentation you also can meet with the former designation "P sensor" for MAP sensor.

We deliver together with matting connector, pins, gaskets, plugs and a USB cable to the computer. If you buy a flash drive here, we will upload all the documentation, SW and PC application to it, everything is also freely downloadable on this page, in the Documentation section. We no longer provide the CD disk in the set.

The product MASTER ignition is a brand new series of ECU units without any direct succession to the previous models. It is the experience in development of industrial and transport safety systems, ignition units and particularly our customers’ needs which provided a foundation for the idea and realisation of the new model.

The unit MASTER ignition has been functionally designed in order to control advance or injection of combustion engines ranging from one to sixteen cylinders (depending on type), with whatever configuration of scanned teeth, types of sensors and features like 5D maps of advance and injection control, integrated pressure sensor, temperature, tachometer output, strobe lamp, charging control, engine speed and turbo preassure PID regulation, control switching on of fuel pump. MASTER unit contain CDI, TCI or combined outputs.

The list of features mentioned above determines MASTER ignition to be used either for a service or tunning replacement of all conventional motorcycle or automobile ECU units, usable for ignition or injection coil control. The integrated redundancy of sensing, together with other key features makes Master ignition very suitable for marine and aviation applications, moreover, thanks to the wide range of operating revolutions can be also used for turbines.

The function of MASTER ignition relies on FPGA technology, which provides digital-analog conversion of sensor signal, as well as its evaluation and calculation of the mathematical model of the real rotation. Simultaneously, it deals with other operations i.e. redundancy sensing, total control of CDI converter, advanced features and signal records. FPGA technology is interesting not only for its high operating performance but particularly for its accuracy, which in principle microprocessor-based systems cannot achieve.

Available units

The MAP - Vacuum Sensor is suitable for 4 or more cylinder motors, allowing you to further capture the engine's negative pressure, thus indirectly positioning the damper on the engine, helping to optimize the overrun and thus improve engine performance.

TCI = output for inductive ignition coil or injection or other use

CDI = output for capacitive igniton coil

Besides these TCI/CDI outputs which differ units, there are available 4 analog/digital outputs, 2 digital inputs and 2 inputs for rotation sensor plus integrated pressure sensor, at every type of unit listed below.

DIN brackets - On request, any unit can be fitted with an aluminum bracket for the DIN rail.

STANDARD 4 outputs variation; aluminum housing with one black (TYCO) connector, without CAN-BUS:

- MASTER ignition MAP sensor 2TCI 2CDI – 12V (2× output TCI, 2× output CDI, 7 – 21V)

- MASTER ignition MAP sensor 1CDI 3TCI – 12V (1× output CDI, 3× output TCI, 7 –21V)

- MASTER ignition MAP sensor 4CDI – 12V (4× output CDI, 7 - 21V)

- MASTER ignition MAP sensor 4TCI – 12V (4× output TCI, 7 - 21V)

- MASTER ignition MAP sensor 1TCI 3CDI – 12V (1× output TCI, 3× output CDI, 7 – 21V)

- All these variations above are possible for 24V (12V – 36V), on demand, please state a note in your order.

EXTENDED 10 or 12 outputs variations, in longer aluminum housing with connector from both sides, with CAN-BUS:

- MASTER ignition MAP sensor 10TCI – 12V (10× TCI outputs, 7 – 21V)

- MASTER ignition MAP sensor 10CDI – 12V (10× CDI outputs, 7 – 21V)

- MASTER ignition MAP sensor 4CDI 6TCI – 12V (4× CDI outputs, 6× TCI outputs, 7 – 21V)

- MASTER ignition MAP sensor 5CDI 5TCI – 12V (5× CDI outputs, 5× TCI outputs, 7 – 21V)

- MASTER ignition MAP sensor 12TCI – 12V (12× TCI outputs, 7 – 21V)

- MASTER ignition MAP sensor 6CDI 6TCI – 12V (6× CDI outputs, 6× TCI outputs, 7 – 21V)

- MASTER ignition MAP sensor can also be made in different combination like 3CDI 7TCI, 4CDI 8TCI, or other combination you need, please order by email.

- All variations are also possible for 24V (12V – 36V), on demand, please state a note in your order.

Table of the use of different types of the MASTER series with different numbers of cylinders and coils

USB flash disk with all documentation and PC application:

If you buy a flash drive at the very bottom in Recommended accessories (here), we will upload all the necessary documentation and software to it.

Otherwise, these files are also freely downloadable below.

Main Features

- The power supply range of 7 to 36 V (depending on type)

- Working speed from 0 to 120 000 rpm

- Operating temperature -40 to 85 °C

- Based on FPGA technology and microprocessor support

- Mathematical model of the real engine rotation, 64bit

- Adjustable pick up sensing levels, A/D conversion of signals, ± 25.5 V, 1Msps

- Angular maps of teeth, the voltage levels for different speeds, filters capture

- Customizing the input type sensor: Induction, Hall, Optical, Hammer

- Redundancy of sensing and other integrated elements

- Advance and Injection control – optional 5D map of ±360° and 0 to 60ms

- Integrated pressure sensor -80 to + 150kPa (depending on type)

- Integrated oscilloscope, runtime visualisation of pick up and switching, ± 25.5 V, 1Msps

- Outputs – MOSFET and IGBT automotive – TCI, CDI or combined, 4 to 10 outputs

- Advanced functions – temperature, vacuum, vibration, tachometer, charge

- Integrated and configurable CDI converter 450V with superb performance of 100W

- User configuration by PC – while in operation with possibility of status visualization

- Galvanic isolated USB – common ground USB protection and EMC disturbation

- Measurement of voltage, temperature and load of converters

- Records – long-term and common, engine hours

- Convenient Firmware Upgrade – regulary and easy updates via the website

- Rapid diagnosis function using LED

Technical parameters

| Parameters | Range |

| Supply voltage | TCI … 7 – 36V CDI(12V) … 7 – 21V CDI(24V) … 12 – 36V |

| Current Consumption | TCI … < 100mA CDI … 0–10A, Dependent on the speed and voltage |

| Working speed (range management) | 0 – 120 000 rpm (0.1 – 65 000 rpm) |

| Working temperature | -40 – 85°C |

| Input mode (PA, PB) | ±25.5V, ±0.1V – ±50V, sampling 1Msps |

| Input mode (PA, PB) | ±25.5V, ±0.1V – ±50V, sampling 1Msps |

| Maps advance [1]…[8] | ±360°, 8 × 1024 pts, (0.1–65 000 rpm) |

| Maps injection [1]…[8] | 0–30ms, 8 × 1024 pts, (0.1–65 000 rpm) |

| Switching coil (1OA, 1OB, 1OC … 1OH) 2×, 4× or 8×, TCI, CDI (dependent on type) |

TCI … MOSFET automotive 25A/300V CDI … IGBT automotive 16A/600V |

| Digital inputs (DI1–DI4) | 0 – 2V = L, 3 – 16V = H (Pull up 1kΩ) |

| Analog inputs (AI1–AI4) | AI1, AI2 … 0–5V; AI3, AI4 … 0–5V/0–10kΩ |

| Digital outputs (DO1, DO2) | MOSFET 5A/100V (Pull up 1kΩ) |

| Measurement of voltage (power supply) | 7 – 50V (tol. ±2%) |

| Temperature measurement (inside housing) | -40 – 125°C (tol. ±2°C) |

| CDI converter (voltage, pulse current, efficiency) | 100 – 450V, 2 – 24A, efficiency 62 – 75% |

| Resistance of primary winding coils* | CDI – Capacitance, resistance 0.1–1.5Ω TCI – Induction, resistance 0.2–25Ω (Pull up 1kΩ) TCI – Injection, resistance 0.2–25Ω (Pull up 1kΩ |

| Memory record | 8kB RAM, 8MB FLASH |

| Status indication by LED | Blue, Red |

| User Configuration - USB | Freeware software MASTER control |

| Protection cover | IP65 |

| Package size | 100×105×37 mm 150x105x37mm (extended) |

| Weight | 350g - 700g (depens on unit type) |

* measured between terminals 1 (switching) and G (ground) for capacitive coil or 1 and 15 (supply) induction

Connector plugging – standard

| Marking | Meaning | Range, Active Level |

|---|---|---|

| + | Voltage suply | 7 – 36V |

| G | Earthing power, sensors | 0V |

| 1OA-1OH | Switching coils A-H or user output | CDI – Capacitance, resistance 0.1 – 1.5Ω TCI* – Inductive, resistance 0.5 – 5.0Ω (Pull up 1kΩ) TCI* – Injection, resistance 0.5 – 5.0Ω (Pull up 1kΩ) |

| +PV | Power sensors output | +5V, 100mA |

| PA, PB | Rotation sensor A,B | ±25.5V, minimum 0.1V, sampling 1Msps |

| AI1–AI4/DI1–DI4 | Analog input AI1…4 Digital input DI1…4 |

AI1,AI2: 0–5V; AI3,AI4: 0–5V/0–10kΩ DI1,DI2: 0–16V; DI3,DI4: 0–16V (Pull up 10kΩ) |

| DI1, DI2 | Digital input 1,2 | 0 – 1V = L, 3 – 36V = H |

| DO1, DO2 | Digital output 1,2 | MOSFET 5A/100V (Pull up 1kΩ) |

* TCI outputs it can be used for injection coils – switching, connection scheme is same as TCI

Connector plugging – extended

| Marking | Meaning | Range, Active Level |

|---|---|---|

| G | Earthing power, sensors | 0V |

| VI | Mechanical vibration frequency inputs | 0–20kHz, 0–1V |

| 1OE-1OS | Switching coils E-S or user output | CDI – Capacitance, resistance 0.1 – 1.5Ω TCI* – Inductive, resistance 0.5 – 5.0Ω (Pull up 1kΩ) TCI* – Injection, resistance 0.5 – 5.0Ω (Pull up 1kΩ) |

* TCI outputs it can be used for injection coils – switching, connection scheme is same as TCI

Preview of application

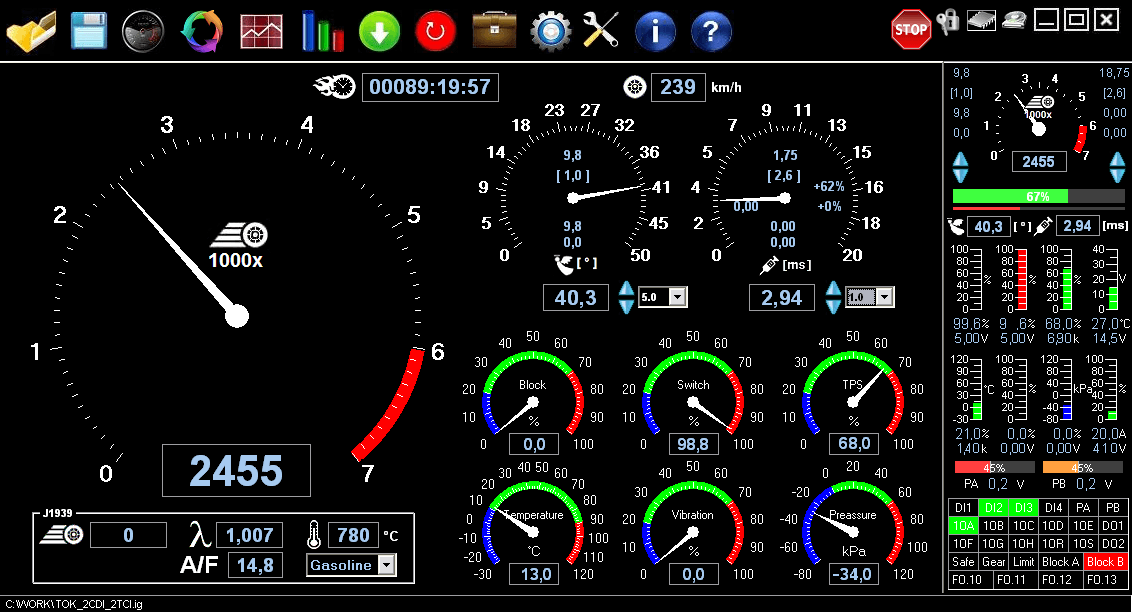

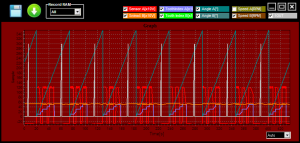

Online visualisation

This is an operational display of function and status of ignition unit MASTER. In order to have functional display it is necessary to have USB connection and switch power supply on.

Visualised data

- Speed (rpm) and advance of engine [°]

- Sensor voltage PA, PB [V]

- Power supply [V] and Temperature [°]

- Converter CDI – Voltage [V], pulsed current [A] and load [%]

- Signals 1OA - 1OH, DI1, DI2, DO1, DO2, AI1, AI2, PA, PB

- Engine hours [s]

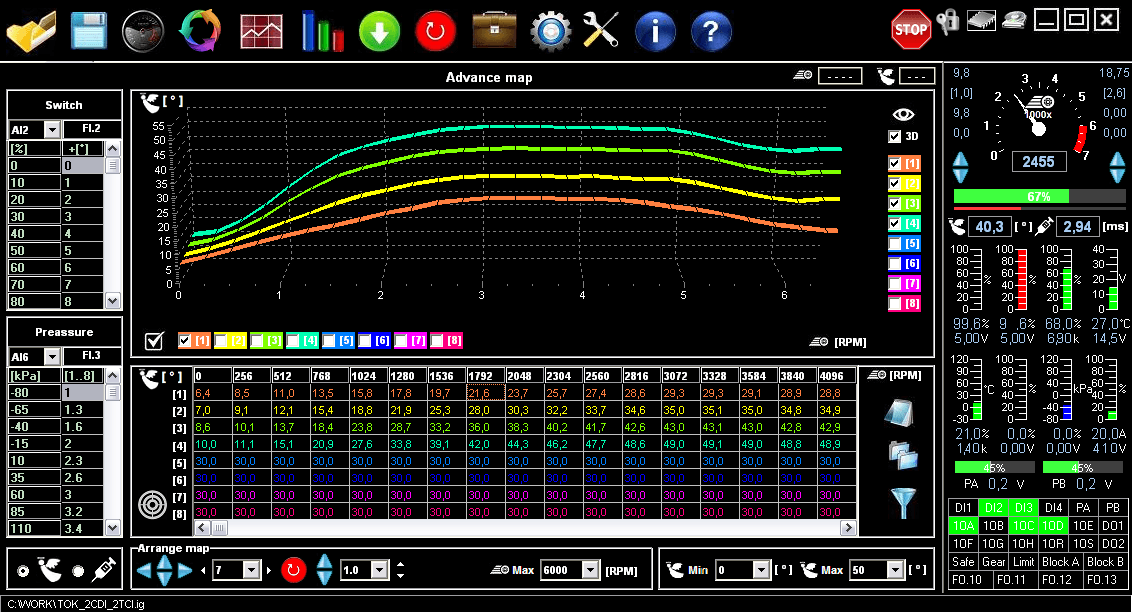

Maps of advance

Maps provide a fast tool to display and model individual curves in advance [1] – [8] in full angle range ±360°. The given figure influences the moment of output switch from 1OA to 1OH. By using digital (DI1, DI2) or analogue outputs AI1, AI2, PA, PB) it is possible to operationally switch among the maps.

Modelling tools:

- Editor maps in advance – quick draw of maps according to specified points

- Mouse modelling – direct editing of maps is possible by mouse movement

- Map shifting – whole map shifting or selected parts only

- Copying – copies of maps one to another of your choice

- Table – direct entry of specific points into table

- Filter – in-progress filtration, rounding the edges of maps

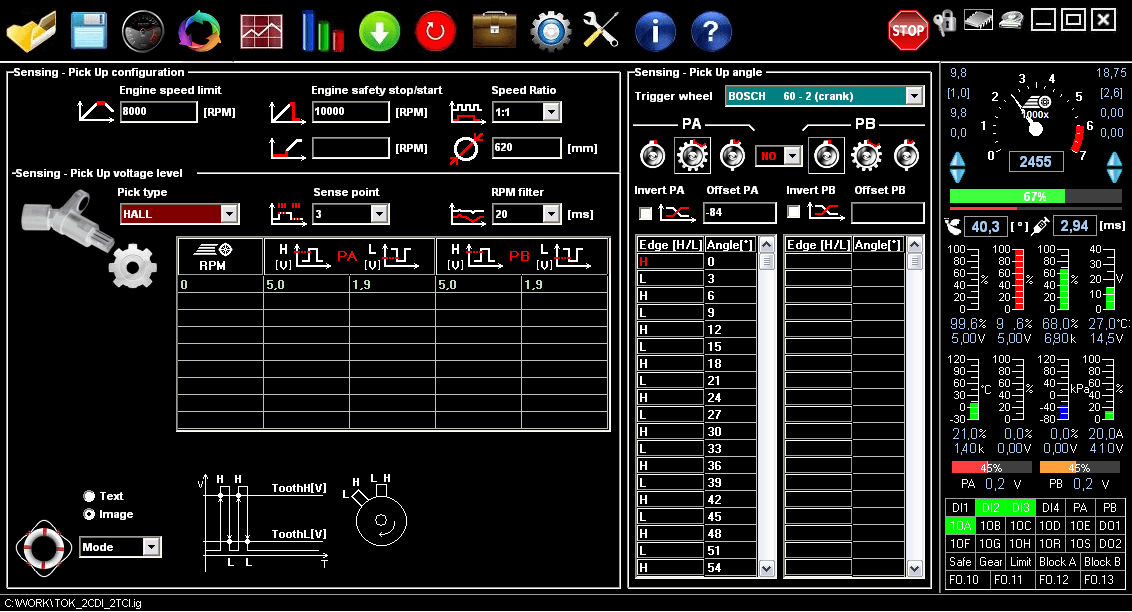

Sensing configuration

Configuring the sensing of engine rotation is the key part of ignition unit MASTER ignition. Within its setting it is possible to select Pick Up voltage sensing level and adapt this level for more range of engine speed. There are other settings to be selected such as filter setting, angles of Trigger Wheel teeth maps or alternatively second level of voltage for synchronisation.

Pick Up voltage sensing level and Trigger Wheel teeth map are predefined for many application Eg. BOSCH 60-2, BOSCH 36-2, BOSCH 2+1, BMW 36-1, FORD 36-1, SUZUKI 24-2, YAMAHA 16-2, HARLEY 32-2.

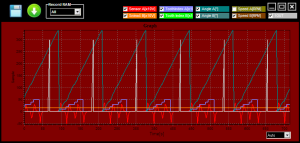

Oscilloscopic record

Oscilloscopic record is used in order to graphically visualise measured and calculated data. This helps to quickly evaluate the proper and accurate function of ignition unit MASTER. It can thus evaluate the correctness of voltage sensing, counting teeth of mathematic model of the real rotation and angels of closing of output coils.

An example to be given; curve angle of engine displacement must be regularly and horizontally increased from 0 to 360°. If there is any change of steepness in the curve or the angle is shorten, the problem is to be found either in wrong angle set up, number of teeth, the type of synchronisation or unsuitable voltage for sensing.

Visualised data:

- Rotation sensor voltage, PA, PB [V]

- Tooth index of sensed blade, Tooth index A-B [-]

- Engine displacement angle, Angle A-B [°]

- Engine revolutions, Revolutions A-B [%]

- Outputs closing 1OA-1OH [-]

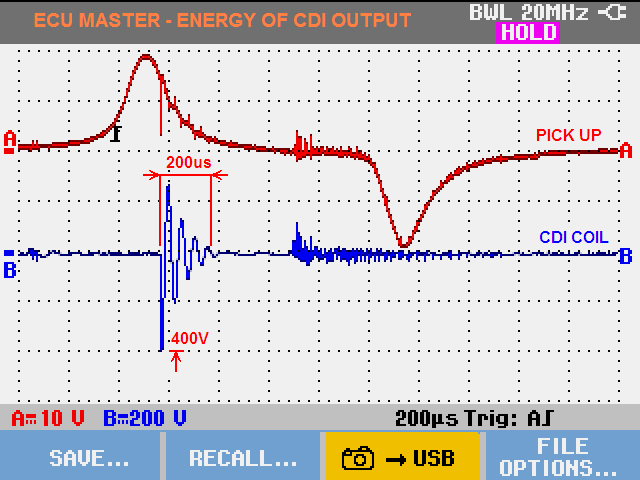

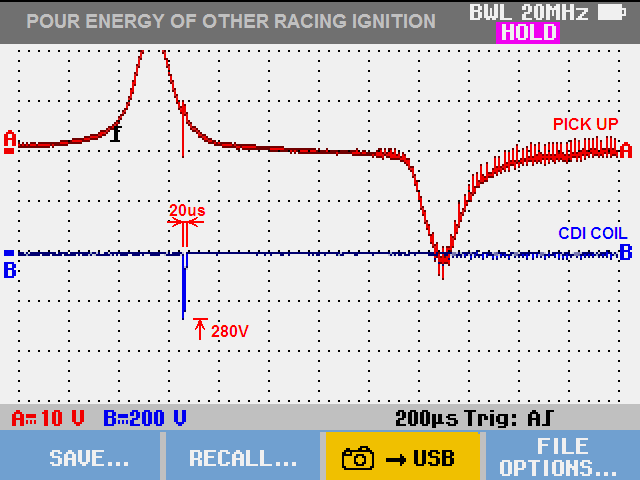

Spark performance

Comparison of spark performance between MASTER ignition and competitive ignition.

Videos

Software tutorial

Reference videos

USB flash disk with all documentation and PC application:

If you buy a flash drive at the very bottom in Recommended accessories (here), we will upload all the necessary documentation and software to it.

Otherwise, these files are also freely downloadable below.

Documentation

| Name | Date | File |

|---|---|---|

| MasterFAQ_EN [pdf, 2.3 MB] | 11.06.2024 | Download |

| J1939_CANopen_Protocol [pdf, 50kB] | 17.04.2019 | Download |

| MasterSchemeV8_43_EN – Schemes and configurations [pdf, 2.3 MB] | 12.06.2018 | Download |

| MasterCDI_TCI_V8_43_EN - instructions [pdf, 3.0 MB] | 12.06.2018 | Download |

| Certificate_ITC_Zlin_EN [jpg, 427 kB]] | 20.06.2014 | Download |

Application Software

| Name | Date | File |

|---|---|---|

| PC application V8.46 MASTER control – [zip, 976 kB] | 04.07.2025 | Download |

| *.ig file examples – [zip, 2,46 MB] | 03.06.2024 | Download |

| USBdriver_v2.12.36.4 [zip, 3618 kB] | 08.04.2024 | Download |

| Ignore Serial Number Utility (Windows XP) [zip, 64 kB] | 02.11.2014 | Download |

| Example of DATALOGGER file [csv, 234 kB] | 06.02.2015 | Download |

Available Variants

| Name | Cena s DPH | |

|---|---|---|

| MASTER ignition MAP sensor – Type 4TCI | 430.76 € | |

| MASTER ignition MAP sensor – Type 4CDI - 12V | 494.89 € | |

| MASTER ignition MAP sensor – Type 2CDI 2TCI - 12V | 494.89 € | |

| MASTER ignition MAP sensor – Type 1CDI 3TCI - 12V | 494.89 € | |

| MASTER ignition MAP sensor – Type 3CDI 1TCI - 12V | 494.89 € | |

| MASTER ignition MAP sensor – Type 10TCI | 545.71 € | |

| MASTER ignition MAP sensor – Type 12TCI | 601.37 € | |

| MASTER ignition MAP sensor – Type 4CDI 6TCI - 12V | 613.47 € | |

| MASTER ignition MAP sensor – Type 6CDI 4TCI - 12V | 613.47 € | |

| MASTER ignition MAP sensor – Type 5CDI 5TCI - 12V | 613.47 € | |

| MASTER ignition MAP sensor – Type 10CDI - 12V | 613.47 € |

Recommended Accessories

-

Inductive coil I05 (TCI)

Common applications, 2x Output, Resistance = 0.6 Ω

-

Temperature sensor T02

Engine temperature sensing

-

Hall sensor H03

Engine speed sensing from zero speed, three wires

-

Inductive ignition coil I04 (TCi)

Cogeneration units, 1x Output, Digital - integrated transistor

-

Inductive sensor S04

Inductive pick up sensor, suitable for wide trigger wheels

-

Inductive coil I06 (TCI)

Common applications, 2x Output, Resistance = 0.6 Ω

-

USB flash disk

USB flash disk - uploaded with SW and documentation

CZ

CZ