Jawa - CZ - Trabant ignition

The ignition enable excitation of two coils with integrated optical rotation reading sensor.

There is instalation guide for motocycles: Jawa 250, Jawa 350, CZ 125, CZ 175, CZ 250 and for automobile Trabant.

Technical Specification

All the functions and optional working ignition regimes can be set by a personal computer. For this reason there is an Ignition Control application that also enables online visual control of real values of turns, pre-ignition (set-up time). Connection with PC is realized with RS232 cable (included) with USB connection.

The pre-ignition directing is realized by the ignition microprocessor which sets the delay time of ignition (the ignition advance) according to the specified curve and actual turns. Just one digital input can change over the ignition curves. The pre-ignition directing is realized by the conversion of asked pre-ignition curve into schedule of time delays. Depending on actual turns of a motor the individual time delays are chosen from the schedule and via the microprocessor exactly measured and that is how the final effect of set up directing works.

The application Ignition Control also provides the function of pre-ignition debugging by acceleration brake where the acceleration of motor is watched when repressing its own mass. The condition is that acceleration of motor turns is adequate to the twisting moment.

Main features

- The induction ignition type - TCI

- Reflection Pick up, 2x outputs TCI, 1x digital inputs

- Supports only one tooth per revolution

- Managed to advance the principle of time delay

- Temperature sensing alarm or blocking

- Limited support TCI coils, Resistance > 2,5Ω

- 2D maps of advance

- Supplay voltage range 3,5 to 25V

- Engine working speed 0 to 25.000 rpm

- Working temperature range -40 to 85°C

- Used connectors - FASTON

- Protection cover IP54

- Communication by RS232/USB

- Two selectable advance curve

- Selectable exciting inductive coil curve

- Extended function DI1

- Change curves during engine work

- Observation actual state of engine

- Engine work time record

- Acceleration brake

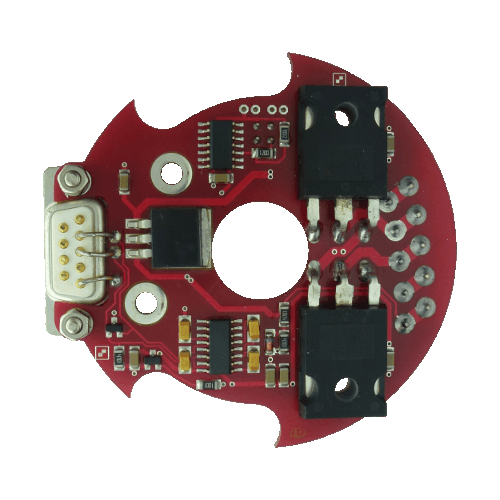

Fotodocumentation

Set of ignition

Main Features

| Parameters | Range |

| Supply voltage | 3,5 to 25V (overvoltage protection 33V) |

| Engine working speed | 0 to 25.000 RPM |

| Advance control | 0 to 90° |

| Working temperature | -40 to 85°C |

| Engine speed for advance control | 180 to 20.500 RPM |

| Flash energy | Table, Max., Med., Min., Direction |

| Coil current | max. 15A/0,085Ω |

| Inductor resistance | > 2,5Ω (12V) a > 1,5Ω (6V) |

| Digital input (DI1) | 0 to 1V = L, 3 to 20V = H |

| Auto. disconnection inductors | 5 to 120s after stop of engine |

| State signalization by LED diode | Red, Green |

| Communication with PC through USB | yes |

| Protection cover | IP54 |

| Package size | 75x71x25 mm |

| Weight | 150g |

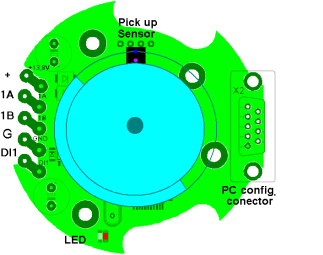

Connector scheme

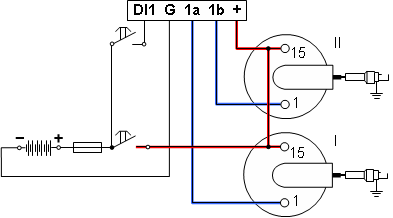

Installation scheme

Main scheme in variant with two inductors.

Input DI1 needn't connect. It is extension function only. For engine with one inductors you must connect 1a output only

Wiring scheme with plus on the frame

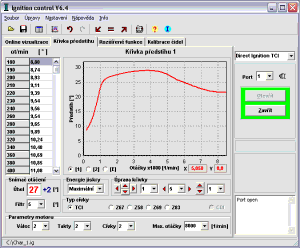

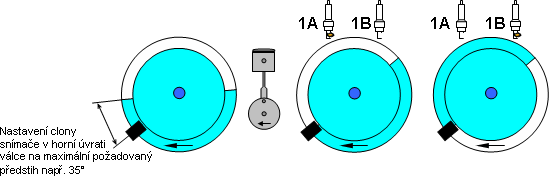

The advance set up

The last and the most important point in the installation are the proper settings of the ignition to serve all demanded functions perfectly.

First it is necessary to know what maximal pre-ignition advance each engine demands in the first period. This maximal pre-ignition advance must be set in the reading sensor of rotation (e.g. 35°) and also be held as a reference value in the program in a Pre-ignition curve bookmark, item Rotation Reading Sensor. Always the value of pre-ignition set in the sensor must be adequate to the value set in the program. According to this value the conversion of the ignition advance curve is saved in a schedule, mainly the actual truth of On-line visualisation.

The value of advance on the rotation reading sensor can be corrected later by comparing the actual value of ignition found out e.g. by a stroboscope to the value of advance set in On-line visualisation.

Signal indicator

The profile of all functions is saved in the ignition memory that keeps data even without power supply. The memory content is recorded from the Ignition Control program.

If the memory has never been recorded or the interruption of the last recording happened this state will be signalized by a short red flashing after switch-on. All set ups will then be given by a producer. The right memory content is indicated by a constant green light. The recording data from the computer is indicated by a red constant light. If the ignition changes into the protective mode (the engine is not running and the regime is allowed) the green indicator stops lightning (the inductors are not being excited). After getting the impulse from the rotation reading sensor the green indicator will switch on again (re-excitation).

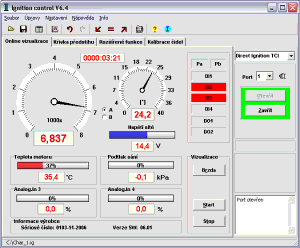

Ignition Control application

The electronic ignition consists of many functions and their set-up can be realized by a personal computer with Ignition Control program. The computer communicates through the RS232 interface of speed 19200Bd. That is why the computer must have at least one COM port. The USB/RS232 transducer we supply in set. The application works under the Windows 95 or higher. It requires 4MB of empty space in hard disc. The minimum PC configuration is Pentium 166MHz, 32MB RAM is accurate.

Ignition Control Program is divided into four individual parts:

- Online visualisation

- Ignition advance curve

- Extended functions

Online visualisation showing this parameters

- Engine RPM

- Engine advance

- Digital input DI1

To run visualization it is always necessary to connect the computer with the ignition by a serial extended cable, to open the communication port and to run the visualization by pressing the button Start. In case that after pressing the button Start the real data do not display please control the connection of communication cable, the number of the used communication port and the voltage of the ignition.

The ignition advance curve

The basic character of the ignition is the directing the ignition advance according to real turns of the engine. To set ignition advance directing characteristics there is Ignition advance curve bookmark.

Flash energy

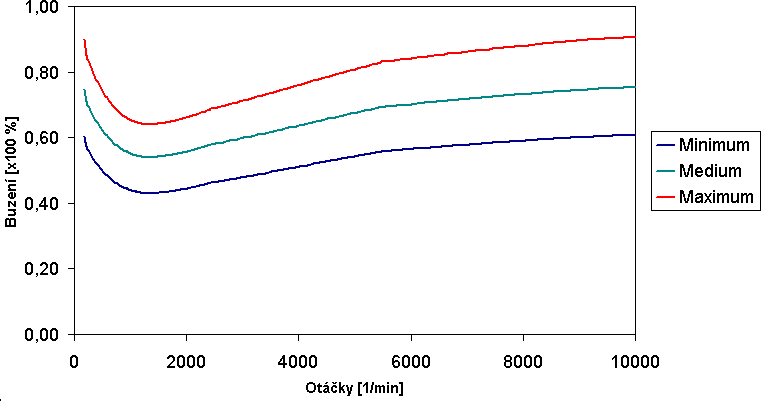

To optimize the type of the inductors and its excitation there is Flash energy button. It is necessary to set medium or minimum excitation that will protect the inductors against the over excitation and their over heating when using inductors with resistance lower than 4ohm (min 3,5 ohm). If using the inductors with the resistance higher than 4ohm there is medium or maximal excitation settings. The settings of Flash energy directing that directs excitation according to values of board voltage is the compromise of the excitation inductors.

| Board voltage | Control flash energy |

| < 3300RPM | Minimum |

| 3300 - 6500RPM | Medium |

| > 6500RPM | Maximum |

The course of the excitation is possible to set by your own modeling curve or by specifying a table. You can choose excitation in the range 20-95% of a round time. You can easily compensate the major disadvantage of inductive ignition which is a drop in current with an increase in speed. Suitable course adds excitation for start and then drops to idle excititation and then increases again with speed, see Predefined graph excitation waveforms.

Pre-defined process of coil exciting

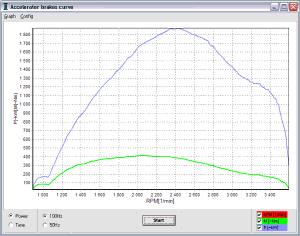

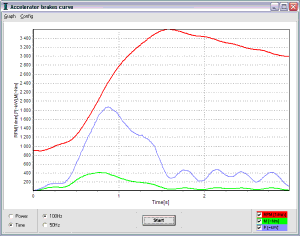

Acceleration brake

There is a function in Online visualization - Acceleration brake that realizes fast 5 second engine record with the calculation of the turn derivation (acceleration). It proportionately responds to torsional moment.

Measure process

- Check the Engine Turn Limits settings before use

- Leave the engine run idly and get ready for its acceleration

- Press Start button

- Wait exactly 1 second to run the record

- Running of the record for 5 seconds

- End up the record and read the measured values of turns from ignition

- Display and conversion the measured values to the graph

Why you should use the Jawa - CZ - Trabant Ignition

The electronics ignition allows very exactly directing of advance. This provide more of engine power in wide range RPM. The ignition allows very easy engine to start (optimal advance), more power (high energy of flash) and with the rules of economy driving then decrease of fuel consume. The ignition work in guaranteed voltage range from 3,5V to 25V.

Available Variants

| Name | Cena s DPH | |

|---|---|---|

| Jawa - CZ - Trabant ignition – Type Trabant | 134.31 € | |

| Jawa - CZ - Trabant ignition – Type Motocykl | 134.31 € |

Recommended Accessories

-

Inductive igniton coil I01 (TCI)

Suitable for veteran applications, 1x Output, Resistance = 4.5 Ω

-

TRABANT KIT IGNITION

Plug & Play Ignition Kit with ECU MASTER LITE

-

USB flash disk

USB flash disk - uploaded with SW and documentation

CZ

CZ